Kapasitor pemanas induksi air

Kapasitor pemanas induksi air

Kapasitor pemanas induksi berpendingin udara

Kapasitor pemanas induksi berpendingin udara

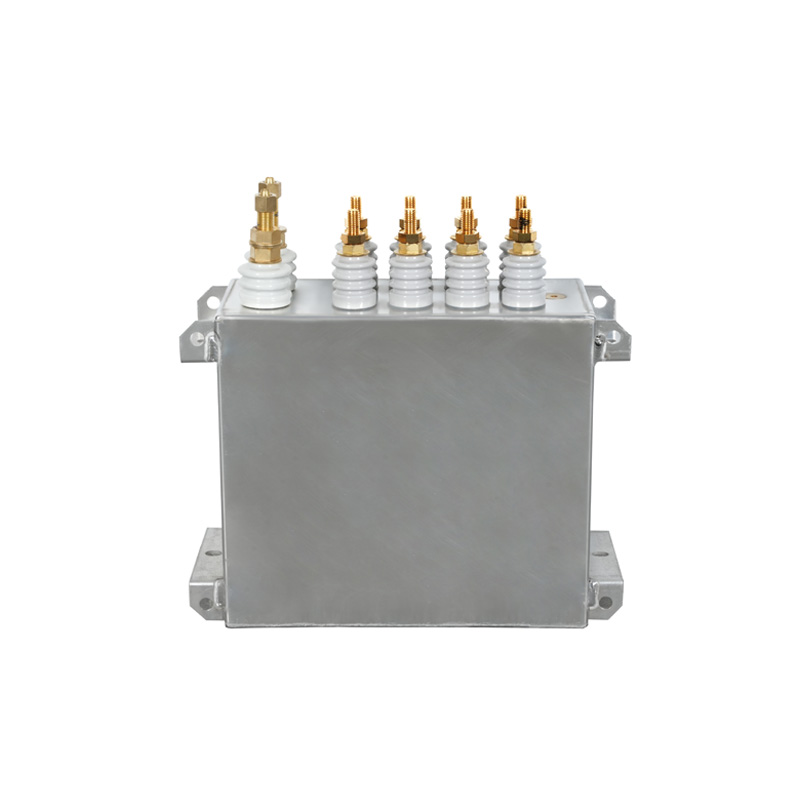

RAM 2200V 3960KVAR 3000Hz Kapasitor pemanasan induksi frekuensi sedang

RAM 2200V 3960KVAR 3000Hz Kapasitor pemanasan induksi frekuensi sedang

Dalam bidang elektronika daya, memastikan arus searah yang bersih dan stabil ...

pelajari lebih lanjutKapasitor Tangki Pemanas Induksi memainkan peran penting dalam s...

pelajari lebih lanjutPemahaman Kapasitor Berpendingin Air Dasar-dasar Kapasitor berpendi...

pelajari lebih lanjutPengertian Kapasitor Tegangan Tinggi — Dasar dan Pentingnya SEBUAHpa itu K...

pelajari lebih lanjutDalam dunia elektronik modern yang kompleks, hanya sedikit kegagalan komponen...

pelajari lebih lanjutMesin Tak Terlihat: Mengapa Kapasitor Pendingin Air Sangat Penting untuk Tekn...

pelajari lebih lanjutKami memiliki tim R&D yang kuat, dan kami dapat mengembangkan dan memproduksi produk sesuai dengan gambar atau sampel yang ditawarkan pelanggan.

Kami memiliki dua pengecoran casting kami sendiri dan satu pabrik pemesinan CNC. Jadi kami dapat menawarkan harga dan produk secara langsung.

Kami memiliki laboratorium pengujian sendiri dan peralatan inspeksi yang canggih dan lengkap, yang dapat memastikan kualitas produk.

Output tahunan kami melebihi 20.000 buah, yang dapat memenuhi kebutuhan pelanggan dengan volume pembelian yang berbeda.

Kami fokus pada pengembangan produk berkualitas tinggi untuk pasar top-end. Produk kami sejalan dengan standar internasional dan sebagian besar diekspor ke Eropa, Amerika, Jepang, dan tujuan lain di seluruh dunia.

Perusahaan ini memiliki tim layanan purnajual profesional dengan personel berkaliber tinggi, pengalaman teknis yang luas, dan peralatan pengujian yang canggih. Berpegang pada pandangan ilmiah dalam pengembangan, perusahaan berinteraksi erat dengan pengguna, terlibat dalam pertukaran teknis yang erat, dan menyediakan layanan produksi yang disesuaikan secara personal. Perusahaan ini mengejar produk yang dipersonalisasi dan terdiferensiasi, mengubah industri manufakturnya dari berorientasi produksi menjadi berorientasi layanan. Melalui mekanisme evaluasi penggunaan produk, perusahaan mempromosikan proyek-proyek kepuasan pengguna, dan berupaya mencapai nol keluhan pelanggan setelah penjualan.

Heat exchange principle: Water-cooled induction heater tank capacitors generate a lot of heat when working. The design of the cooling channel is based on the principle of heat exchange. By allowing cooling water to flow in the channel, the heat generated by the capacitor is absorbed, thereby reducing the temperature of the capacitor. Jiande Antai Power Capacitor Co., Ltd. has 40 years of professional experience. When designing cooling channels, it fully considers the efficiency of heat exchange to ensure that the product can operate stably under various working conditions. The induction heating melting capacitors and other products it produces have effectively solved the heat dissipation problem through reasonable cooling channel design, ensuring the excellent performance of the products, which is one of the reasons why its products have won wide recognition and trust from domestic and foreign customers.

Channel layout: The cooling channel is usually laid out around the heating element of the capacitor to achieve uniform heat dissipation. Common layout methods include spiral and parallel. The spiral channel enables the cooling water to flow in a spiral shape around the capacitor shell, increasing the contact area and contact time between the cooling water and the capacitor, and improving the heat exchange efficiency. The parallel channel is easy to process and install, and can ensure that the cooling water is evenly distributed in a certain area.

Channel size: The size of the cooling channel has an important influence on the cooling effect. If the channel diameter is too large, the cooling water flow rate is large, but the flow rate is low, and the heat exchange efficiency may not be high; if the channel diameter is too small, the flow rate is high, but the water resistance increases, which may lead to an increase in the power of the water pump and easy blockage. Generally speaking, the channel size needs to be determined based on factors such as the heat generation of the capacitor, the flow rate and pressure of the cooling water. During the production process, Jiande Antai Power Capacitor Co., Ltd. will use its own testing laboratory and advanced and complete testing equipment to test cooling channels of different sizes to find the best design solution to ensure product quality.

Optimize the channel inlet design: In order to make the cooling water enter the cooling channel evenly, the design of the inlet is crucial. A diffusion-type inlet can be used to allow the water flow to be evenly dispersed when entering the channel to avoid the situation where the local flow rate is too high or too low. At the same time, a guide plate or diverter is set at the inlet to guide the water flow to each branch channel to ensure the uniform distribution of the water flow.

Adopt reasonable channel shape and structure: The shape and structure of the channel will affect the flow characteristics of the water flow. For example, the use of smooth inner walls can reduce the resistance of the water flow and avoid turbulence or vortexes in the water flow. In addition, setting appropriate spoiler elements in the channel, such as ribs or protrusions, can increase the disturbance of the water flow and improve the heat exchange efficiency, but at the same time, care should be taken to avoid uneven water flow caused by spoiler elements. When designing cooling channels, the R&D team of Jiande Antai Power Capacitor Co., Ltd. will comprehensively consider the shape, structure and arrangement of spoiler elements of the channel to achieve the best cooling effect and water flow uniformity.

Balance channel resistance: In order to ensure that the cooling water flows evenly in each channel, it is necessary to balance the resistance of the channel. For longer or more curved channels, the cross-sectional area of the channel can be appropriately increased to reduce the resistance; for shorter or straight channels, the cross-sectional area can be appropriately reduced to make the resistance of each channel roughly equal. This ensures that the flow distribution of cooling water in different channels is uniform.

Install flow control devices: Installing flow control devices such as flow control valves or flow meters in the cooling system can monitor and adjust the flow of cooling water in real time. By precisely controlling the cooling water flow rate of each channel according to the operating temperature and actual needs of the capacitor, uniform heat dissipation can be achieved.

Regular maintenance and cleaning: Scale, impurities, etc. may accumulate in the cooling channel, affecting the uniformity of the water flow and the heat exchange efficiency. Therefore, the cooling system needs to be maintained and cleaned regularly to keep the channel clean and unobstructed.